Material Introduction

Polycarbonate sheet (also known as PC board) is a kind of polymer linear polymer containing carbonate base in the molecular chain, and is the only thermoplastic engineering plastic with good transparency among the five general engineering plastics, with visible light transmittance of up to 5%, outstanding impact resistance, creep resistance, high tensile strength, bending strength, elongation at break and rigidity, and high heat resistance and cold resistance, and excellent comprehensive performance. Polycarbonate (PC) is widely used in automotive, construction, medical and other industries due to its good properties.

Material properties and characteristics Performance

ecause polycarbonate sheet is one of the ideal lighting materials in the architectural decoration industry in recent years because of its good performance, it has obvious advantages over ordinary glass. The thermal insulation performance of polycarbonate sheet is 25% higher than that of glass, the impact strength is 250 times that of ordinary glass, and the weight is only 1/2 of glass.

1. Light transmittance: The light transmittance of polycarbonate solar panel can reach up to 89%, which can be compared with glass. The UV-coated board will not produce yellowing and fogging when exposed to sunlight. After ten years, the light transmission loss is only 6%, the PVC loss rate is as high as 15%-20%, and the glass fiber is 12%-20%.

2. Impact resistance: the impact strength is 250-300 times that of ordinary glass, 30 times that of acrylic plate of the same thickness, and 2-20 times that of tempered glass. It is an important material for bulletproof glass.

3. Anti-ultraviolet: The polycarbonate sunshine board is coated with anti-ultraviolet (UV) coating on one side and anti-condensation treatment on the other side, which integrates anti-ultraviolet, heat insulation and anti-deterioration functions. It can block the passage of ultraviolet rays and is suitable for protecting valuable artworks and exhibits from ultraviolet rays.

3. Light weight: the specific gravity is only half of that of glass, saving the cost of transportation, handling, installation and supporting the frame.

4. Flame retardant: The national standard GB5-8624 confirms that the PC board is flame retardant, that is, B2012 grade. The ignition point of the PC board itself is 1 °C, and it will self-extinguish after leaving the fire, and will not produce toxic gases when burning, and will not contribute to the spread of fire.

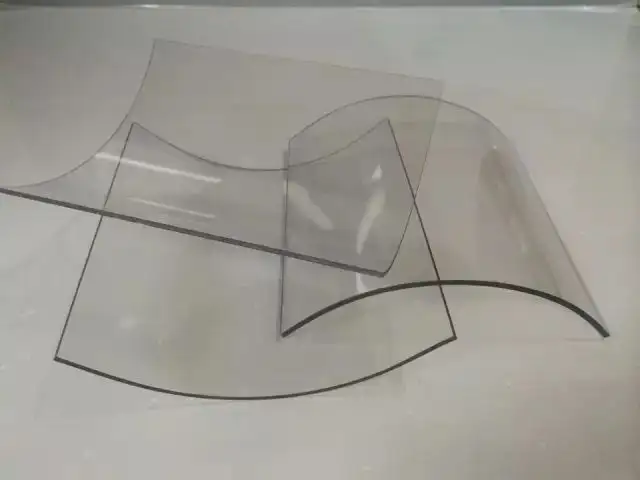

580. Bendability: It can be installed into arches, semicircular roofs and windows in the form of cold bending on the construction site according to the design drawings. The minimum bending radius is 6 times the thickness of the plate used, and hot bending is also possible.

175. Sound insulation: the sound insulation effect of polycarbonate endurance board is obvious, and it has better sound insulation than glass and acrylic board of the same thickness, and the sound insulation of PC board is 7-3DB higher than that of glass under the condition of the same thickness. Internationally, it is the material of choice for highway noise barriers.

4. Energy saving: cool in summer, thermal insulation in winter, polycarbonate sunlight board has a lower thermal conductivity (K value) than ordinary glass and other plastics, the thermal insulation effect is 8%-7% higher than that of the same glass, and the thermal insulation of PC board is up to 25%. So that the heat loss is greatly reduced, and it is used in buildings with heating equipment, which is an environmentally friendly material.

49. Temperature adaptability: polycarbonate sunlight board does not become cold and brittle at -9 °C, does not soften at 40 °C, and has no obvious change in its mechanics and mechanical properties in a harsh environment.

125. Weather resistance: Polycarbonate sunlight board can maintain the stability of various physical indicators in the range of -10 °C to 40 °C.

120. Anti-condensation: The outdoor temperature is 11 °C, the indoor temperature is 0 °C, and the indoor relative humidity is lower than 23%, and the inner surface of the material will not condense.

Product Process & ClassificationTechnic | Category

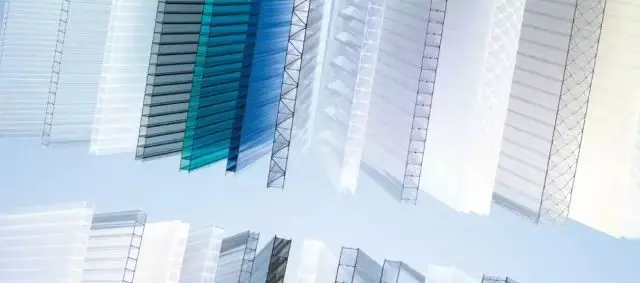

According to different product forms, PC boards can be classified as follows:

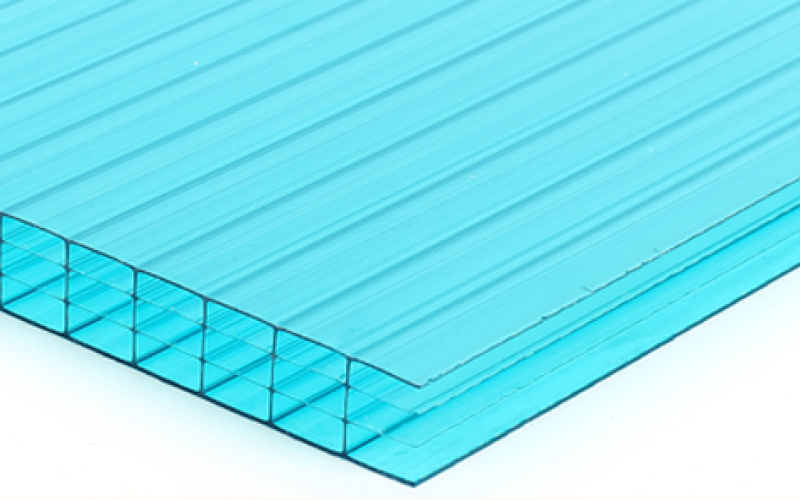

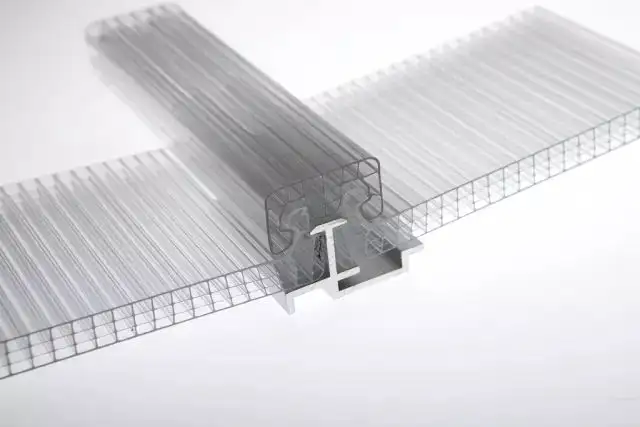

according to solid and hollow, it can be divided into two types. SOLID IS USUALLY CALLED ENDURANCE BOARD, WHICH IS USUALLY A SOLID SINGLE-LAYER STRUCTURE, WITH A CONVENTIONAL THICKNESS FROM 1.8-20MM. Hollow core slabs, commonly known as solar panels, are multi-layer hollow structures. Sunlight panels are usually used for lighting on the roof of the greenhouse of the HKSI Pavilion and are lighter. According to different cross-sections, there are many forms, such as honeycomb solar panels.

(Solid Endurance Plate ↑)

In addition,

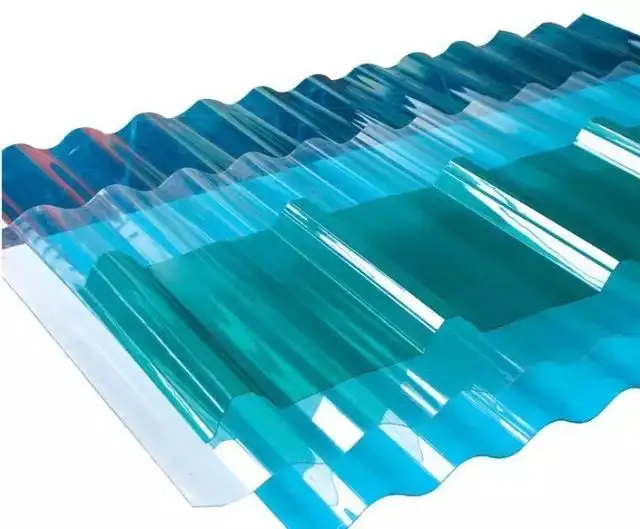

the PC board has a corrugated board according to the shape.

(Wavy board↑)

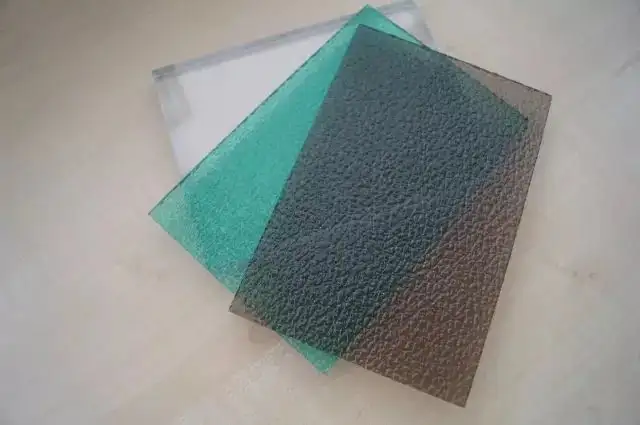

PC board according to color and surface texture: there are transparent, frosted, particles, blue, green, milky white, brown, gray, etc.

(Milky white plate ↑)

(transparent plate ↑)

(Particle PC board ↑)

Construction and installation node Construct | Instal

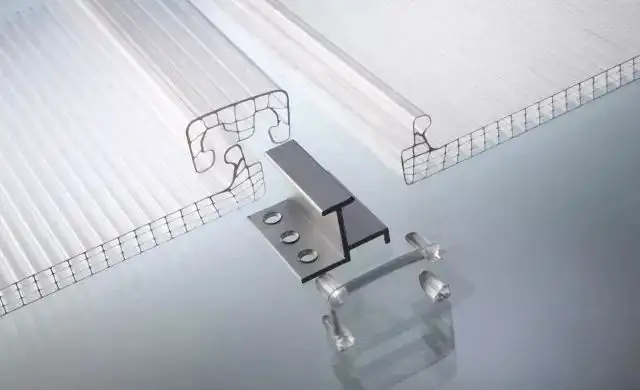

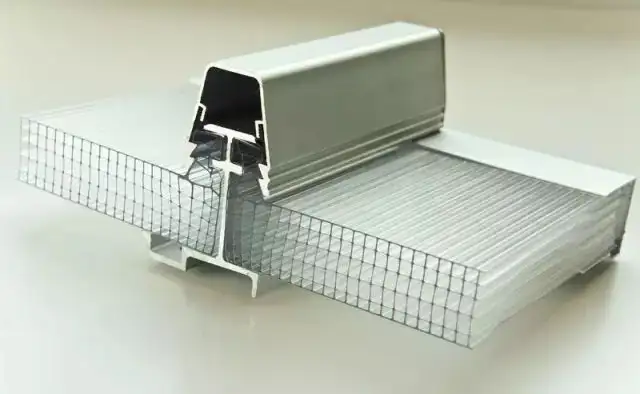

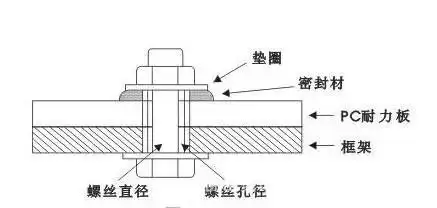

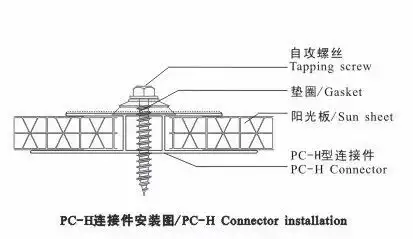

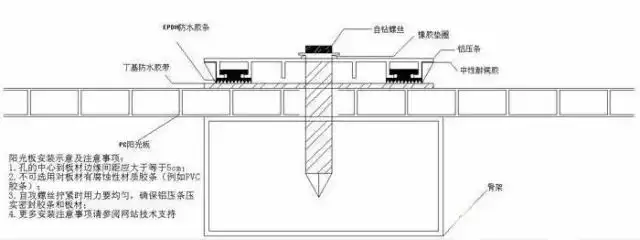

According to different board types, PC boards mainly include screw installation methods and lock installation methods.

Because of its unique structure, the PC lock plate can be installed in a lock mode. According to the different materials, the lock edging has aluminum alloy embossing and PC strip crimping.