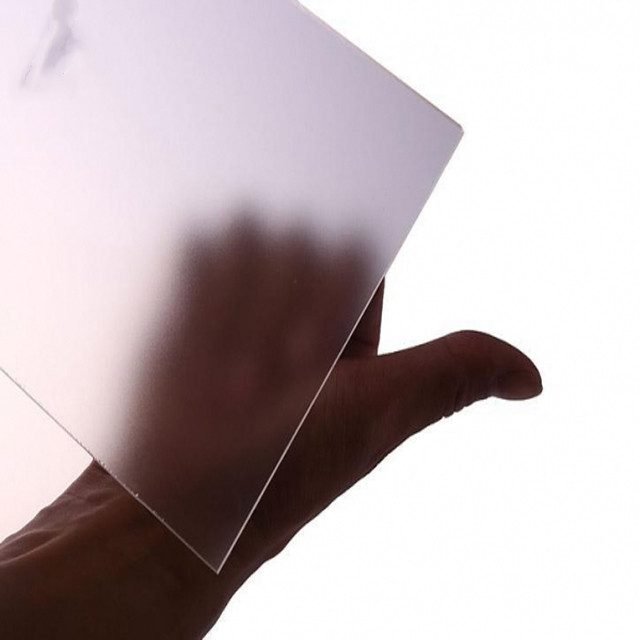

white milk light diffusion Product description

Size of Products | THICKNESS: from 1.3mm to 10mm |

LENGTH: no-limited | |

WIDTH: 1220mm, 1560mm, 1820mm and 2100mm | |

COLOR: white milk Specifications and colors can be customize. | |

Products Features | 1. Light transmission: reach 12%-82% depending upon color and thickness |

2.Fire retardancy: grade B1 is decided by the national GB8624-1997 test, without fire drop nor poisonous gas | |

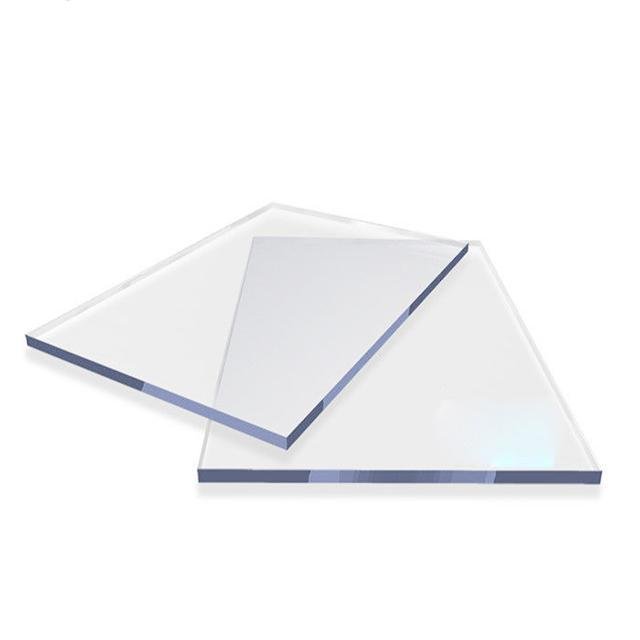

3. Impact resistance: the impact strength of pc sheet is 250-300times as much as ordinary glasses. | |

4.Easy installation | |

5. Sound insulation | |

6.Weather ability: temperature range from -40℃ to 120℃. | |

7. UV-protection |

FEATURE:

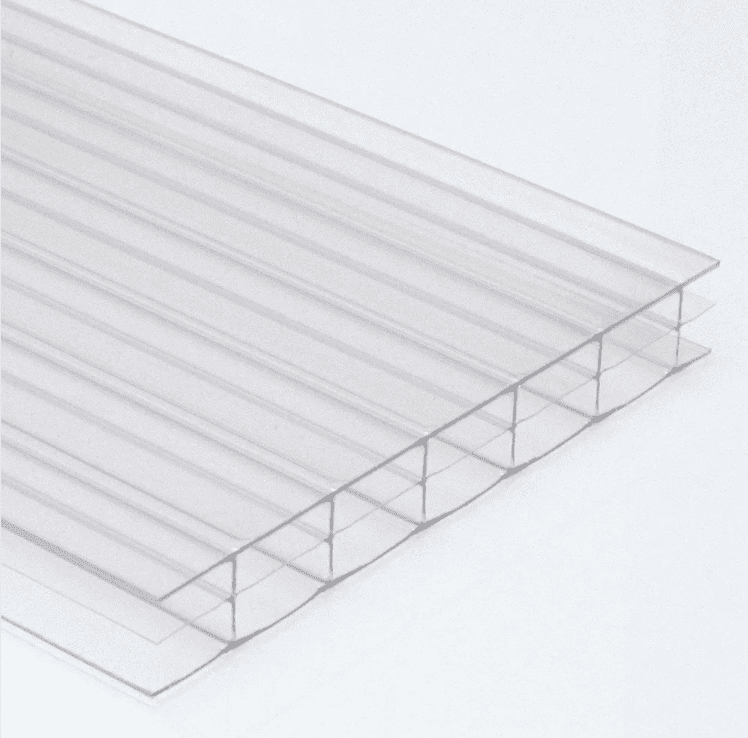

1)Impact strength: The impact strength of PC hollow sheet is 250 times of glass.

2)Light weight: The weight of PC hollow sheet is only about half of glass.

3)Transparency: The light transmission of a 3mm thickness PC hollow sheet is 88%.

4)UV-protection: A PC sheet is co-extruded with a high-density ultra violet ray that also keeps the PC sheet from discoloring.

5)Resistance to weather: PC hollow sheet has resistance to bad weather and maintain excellent performance in the temperature range from -40oCto 12oC

6)Inhibiting condensation: When the outdoor temperature is 0oC and the indoor temperature is 23oC, the PC sheet will be condensation up to 80%.

7)Thermal insulation: The K-value of glass is 1.2 times of PC solid sheet. PC sheets can save energy while preventing heat loss.

8)Sound insulation: 6mm thickness PC hollow sheet can reduce sound 20db.

9)Flame resistance: Through testing by th National center for quality Supervision&Testing of Fire Building materials, the material is rated as Class 1 according to QB8624-1997standard.

10)Easy installation: A PC sheet can be bent while hot or cold and can be used on curved roves and windows. The minimum radius of curvature of a PC sheet is 175 times of its thickness.

The application ranges of PC Solid and Embossed Sheet

1. Building: as a day-lighting ceiling of office buildin Noise barriers of expressways and urban overhead roads.

2. Robbery prevention: Burglarproof counters of banks, treasures booths, safety lighting material of jewelry shops.

3. Advertising: Panels of ad lamp boxes, displaying boards.

4. Blast prevention: Police shields, cash truck windows.

5. General proposes: vending machine panels, motorcycle helmets, protective masks and so on.

Certification:

Other product as following:

1. Q: Are you manufacturer or Trade Company?

A:We are professional factory, have more than 10 years experience of manufacturing high quality polycarbonate sheets. OEM is acceptable.

2. Q:What’s the order process?

a.Inquiry—provide us all clear requirements.

b.Quotation—official quotation form with all clear specifications.

c.Customization— We offers ultimate customization and personalized solutions.

d.Sample —Standard sample of our factory.

e.Payment terms— T/T 30% in advanced, balanced before shipment.

f.Production—mass production

g.Shipping— by sea, air or courier. Detailed picture of package will be provided.

3. Q:What terms of payment you use?

A:T/T, PayPal, Cash.

4. Q: What is your raw material for polycarbonate sheet?

A:We adopt imported material such as Bayer, Sabic, Senyi, Samsung and other famous brands.